Phone: 0086 13510810562

Whatsapp: 0086 13510810562

Email: Teddyworldwide@outlook.com

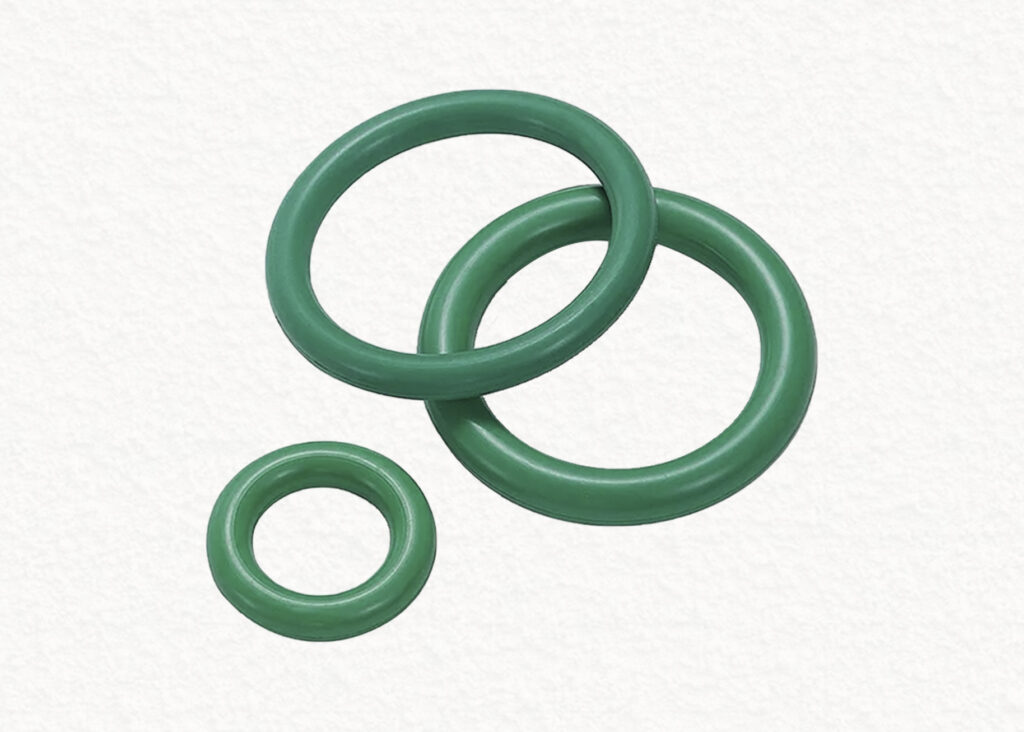

It is a circular rubber sealing ring with a circular cross – section. During installation, the O – ring is compressed in the sealing groove of two matching parts, and the sealing is realized by the extrusion force generated by its elastic deformation, preventing fluid leakage between the two parts.

Common materials include nitrile rubber, fluoroelastomer, silicone rubber, etc. O – rings made of different materials have different properties such as oil resistance, chemical corrosion resistance, high temperature resistance and cold resistance to adapt to different working environments and medium requirements.

Widely used in various mechanical equipment, pipeline systems, hydraulic and pneumatic systems, etc., for sealing static or dynamic joints, such as between the engine block and the cylinder head, at the connection of hydraulic pipelines, and at the sealing part of valves. It is a very commonly used sealing element.