Phone: 0086 13510810562

Whatsapp: 0086 13510810562

Email: Teddyworldwide@outlook.com

Wire Cut Service is a precision machining technology based on the principle of Electrical Discharge Machining (EDM). It uses thin metal wires (typically molybdenum wire or brass wire) as electrodes. Through a numerical control system, it controls the tiny discharge gap between the electrode wire and the workpiece, and utilizes the thermal effect generated by high-frequency pulse current to erode materials layer by layer, achieving cutting.

Tolerances: ±0.0002″ (0.005mm)

CNC-controlled wire electrode for micron-level accuracy

Non-contact EDM machining

Processes carbide, titanium, ceramics (high-hardness/high-melting-point materials)

Programmable 2D/3D contours

No specialized tooling required for hollow/angled/intricate geometries

Wire cut is a key technology in mold manufacturing. It can cut tool steel and carbide with high precision, accurately shaping mold cavities and cores. Its micron - level accuracy ensures consistent mold production, and non - contact machining prevents mold deformation, extending service life.

Wire cut is used to machine aerospace materials like titanium alloys, manufacturing critical components such as engine blades. Through CNC programming, it achieves complex surface machining, ensuring lightweight and high - strength parts, thus safeguarding spacecraft operation.

With high precision and material adaptability, Wire cut enhances production efficiency and quality. It can machine various metals and special materials, precisely cutting complex contours and precision components via CNC programming, reducing errors from tool wear and accelerating production.

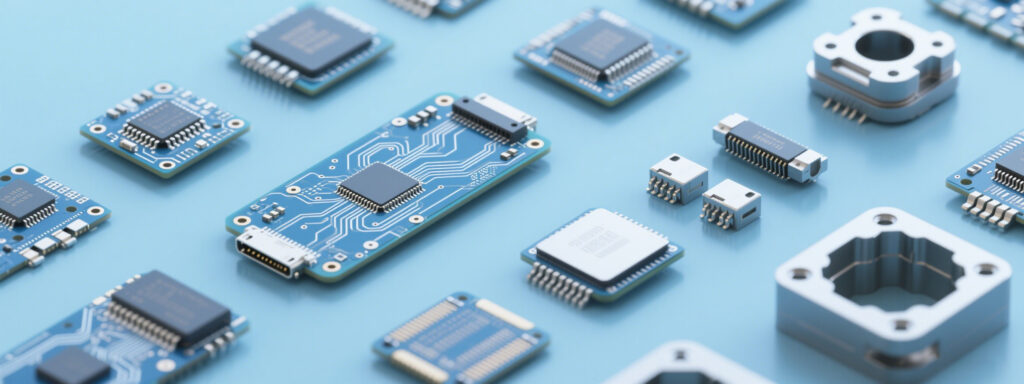

Wire cut meets the miniaturization needs of the electronics industry. It can machine ultra - thin circuit boards, micro connectors, and semiconductor packaging molds, precisely controlling dimensions. Its flexible machining of irregular shapes supports the lightweight design of electronic devices.