Phone: 0086 13510810562

Whatsapp: 0086 13510810562

Email: Teddyworldwide@outlook.com

We are an international business group specializing in the production and export.

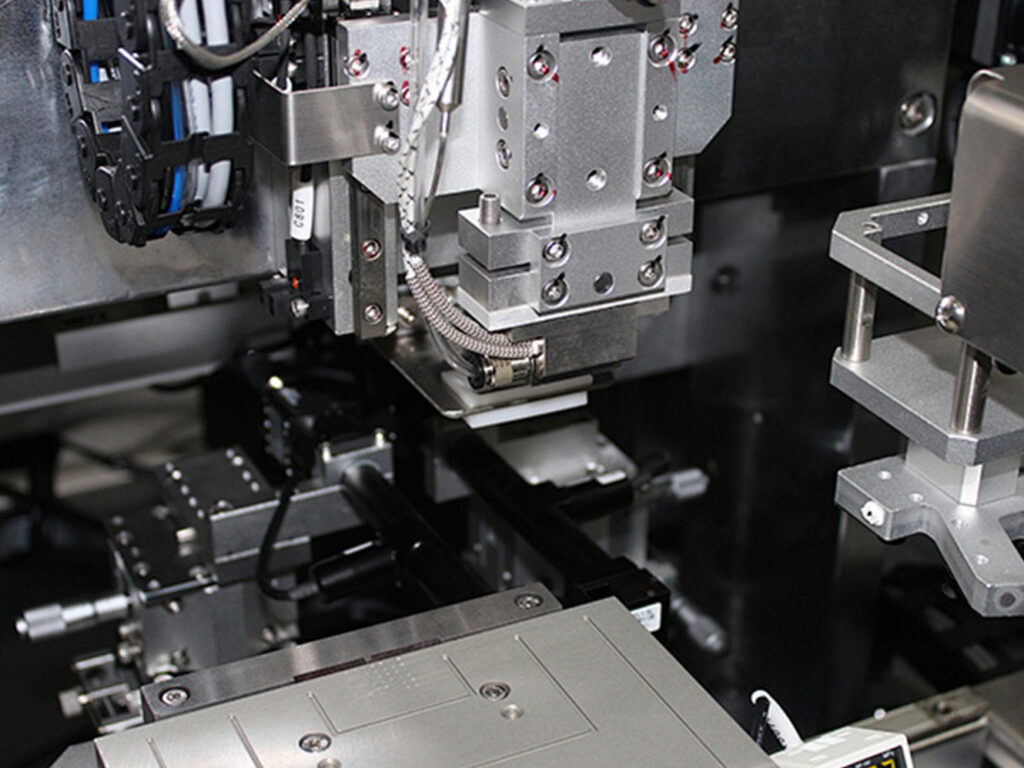

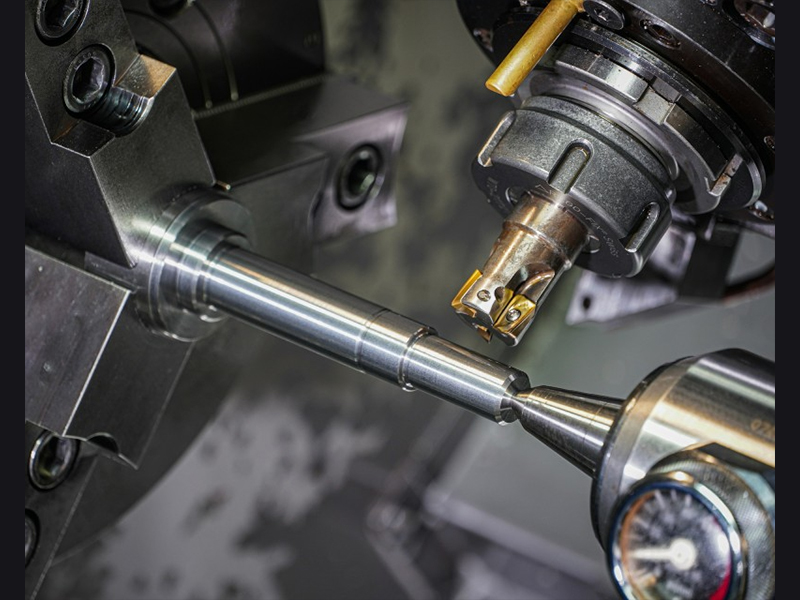

With professional-grade equipment, we optimize efficiency and precision. Our advanced machinery, from high-precision tools to automated systems, enables us to handle complex tasks swiftly and accurately, delivering projects on time with superior results.

Our Technical Team blends expertise with innovation. Comprising skilled engineers and researchers, they stay ahead of industry trends, develop customized solutions, and ensure every project benefits from the latest technologies and best practices.

Quality is our top priority. We enforce strict checks throughout production, using advanced testing to ensure each product meets high standards. Our commitment to excellence guarantees reliability and builds long-term trust with clients.

Precisely machining metals and special materials via CNC-controlled electric discharge, creating complex contours for molds and aerospace components with micron-level accuracy.

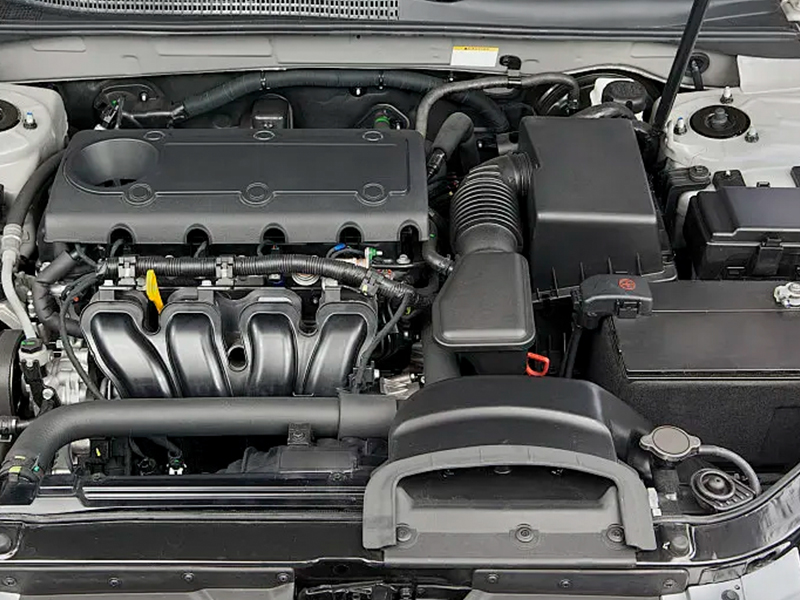

Fabricating high-precision molds for mass-producing plastic parts, integrating fixed/moving components to shape products from automotive casings to medical devices.

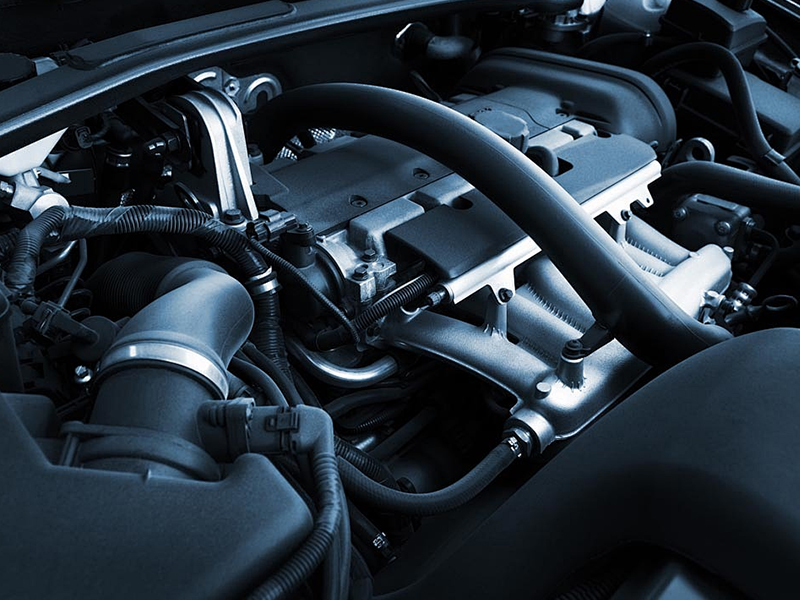

Transforming raw materials like titanium alloys and plastics through techniques like sandblasting and chemical plating to enhance mechanical properties and functionality.

Applying coatings (e.g., electroplating, PVD) and treatments (anodizing, passivation) to improve durability, aesthetics, and corrosion resistance of metal/plastic products.

We integrate advanced technology and professional equipment into our craftsmanship, ensuring precision and innovation in every project. Rigorous quality control guarantees reliable, high-performance seal products that meet strict standards.

Mayzula was founded in 2013. We are an international business group specializing in the production and export. At present, products cover Skeleton Oil Seal, Hydraulic Oil Seal, Valve Stem Seal, Valve Cover Gasket, Motorcycle Brake Pads, O-Ring Seal and other types of seals.

We have passed global certifications such as CCC, SAA, BS, ASTM, WATERMARK, SGS, CE, ACRS, and ISO9001 quality system certification.

We adhere to the business philosophy of "survival through integrity and quality", and customers can purchase with confidence.

Premium Resources Ensuring Superior Durability & Performance Excellence

Personalized Client Care with Tailored Solutions Exceeding Expectations

Certified Expertise Delivering Precision Craftsmanship for Flawless Execution

Ensure on-time delivery through effective and precise scheduling

Endorse products, projects, and services to improve customer satisfaction

Proactive Support Accelerating Issue Resolution & Seamless Communication

Skeleton Oil Seal, Hydraulic Oil Seal, Valve Stem Seal, Valve Cover Gasket, Motorcycle Brake Pads, O-Ring Seal and other types of seals.

Quite reliable. We have a professional design team, advanced equipment, and strict quality control to ensure that every component is carefully selected and of high quality.

Wire Cut is used for processing hardened metals and alloys that are difficult to cut using other processing methods. In addition, the wire cutting CNC machining method can also process parts with complex geometric shapes, hard metals with strict tolerance requirements, parts with excellent surface smoothness, and fine holes.

Our injection mold service covers the whole process of injection molding from molding tooling, plastic injection molding, over molding and insert molding The Service process involves producing parts by injecting molten materials into a mold. It’s a versatile solution for producing high volumes of identical plastic parts.

We process a wide variety of thermoplastics including ABS, Polycarbonate, Polyethylene, PU and more. Contact our technical team for specific material inquiries.

Yes, we have a dedicated design team that can assist in mold optimization and surface treatment to ensure efficient and high-quality production.

Yes, we value continuous customer communication. After multiple communications, we have finally determined your specific requirements. Communication will continue until the parts are delivered to you, in order to maximize the quality and functionality of the parts.

Thank you for leaving your message